Extrusion Screen Changer

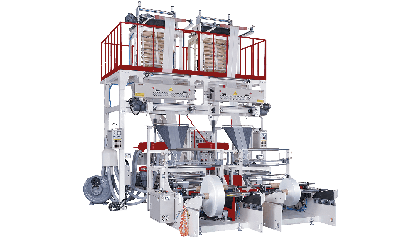

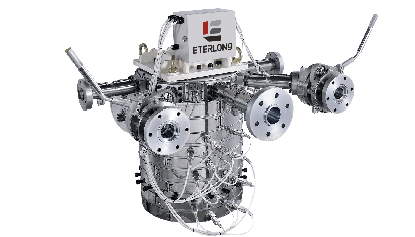

Eterlong Extrusion Screen Changer offers a highly economical and efficient solution for blown film extrusion lines. Designed for ease of operation and minimal downtime, it’s an ideal choice for both mono-layer and multi-layer extrusion systems.

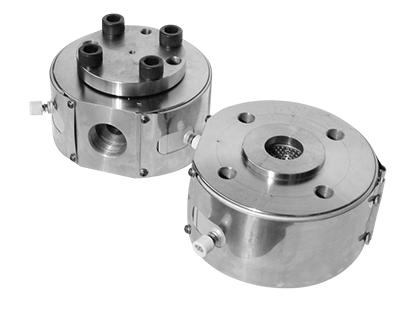

Its compact design allows for seamless integration, and an optional adaptor can be installed to connect directly with the Die Head Feeding System. For enhanced process control, the unit also supports the installation of a pressure sensor, enabling real-time monitoring of pressure variations to ensure consistent product quality.

Key Features of Our Extrusion Screen Changer

-

Efficient Contaminant Removal

– Filters out unmelted resin, gels, and impurities to ensure high film quality. -

Improved Extrusion Stability

– Maintains steady melt pressure and flow, enhancing thickness uniformity and output consistency. -

Reduced Downtime

– Quick-change design or continuous operation (in dual-piston models) minimizes production interruptions. -

System Protection

– Prevents clogging and wear in sensitive downstream components like the die head and calibration units. -

Enhanced Material Flexibility

– Enables the use of lower-cost or recycled materials while preserving end-product integrity. -

Pressure Monitoring

– Compatible with pressure sensors for advanced process control and safety alerts. -

Easy Integration

– Compact and adaptable with optional feed adaptors to suit different extruder/die setups.

Applications of Extrusion Screen Changer

Eterlong’s screen changers are widely used across various plastic extrusion processes to ensure cleaner melt flow, stable operation, and improved product quality:

- Blown Film Extrusion - Enhances film clarity, strength, and thickness uniformity in the production of LDPE, LLDPE, HDPE, and PP films.

- Cast and Sheet Film Lines - Delivers smooth surface finish and precise thickness control for high-performance packaging and industrial films.

- Pipe and Profile Extrusion - Maintains steady extrusion pressure and prevents die blockage, ensuring consistent output and dimensional accuracy.

- Pelletizing & Recycling Systems - Efficiently filters out contaminants to improve pellet quality, extend equipment life, and ensure stable downstream processing.

Why Choose Eterlong’s Extrusion Screen Changer Technology?

Backed by decades of expertise in extrusion system design, Eterlong delivers screen changers engineered for durability, precision, and operational simplicity. Designed to minimize maintenance, extend equipment lifespan, and support continuous, high-quality production, our solutions meet the demands of modern plastic processing.

We understand the real-world challenges faced by film manufacturers and recyclers, and we offer customizable systems that integrate seamlessly into your existing line. For efficient, reliable melt filtration, Eterlong is the partner you can depend on.

STEP 01

Initial Inquiry

STEP 02

Technical Confirmation & Recommendations

STEP 03

Drawings

STEP 04

Manufacturing & In Process Quality Control

STEP 05

Final Quality Control

STEP 06

Packing & Shipping