BLOWN FILM LINE

Eterlong’s blown film line delivers exceptional performance and precision for producing high-quality plastic films across various industries. The line features key components like the Blown Film Extruder, which ensures the proper melting and mixing of raw materials for consistent film production. The Blown Film Take-Up Unit (Haul-Off) flattens the bubble tube into lay-flat film for further processing, while the Blown Film Winder maintains tension and stability, ensuring smooth, even film rolls. This comprehensive system makes our blown film line ideal for producing films used in food packaging, agriculture, and industrial applications, providing superior strength, consistency, and quality throughout the process.

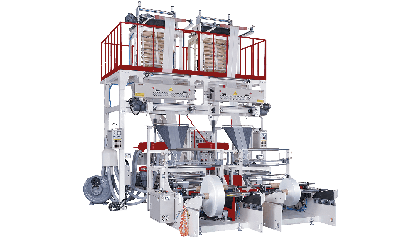

Blown Film Machine

Eterlong’s blown film machines are designed for efficient and reliable production of plastic films used across industries—including food packaging, agriculture, medical supplies, textiles, and industrial applications. Each machine is built with precision extrusion technology to ensure consistent film thickness, high clarity, and mechanical strength.

Our product line includes mono-layer and customizable multi-layer blown film machines models, tailored to meet specific production demands. Whether you're producing LDPE, LLDPE, mLLDPE, HDPE, PP, or composite films, Eterlong delivers flexible solutions with stable output, user-friendly control systems, and energy-efficient operation.

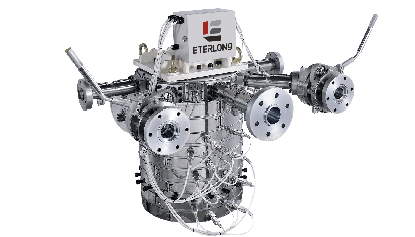

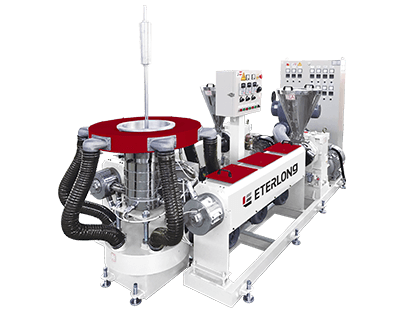

Blown Film Extruder

For the whole process of film blowing, the Blown Film Extruder is one of the most significant devices among the machine to produce plastic film. By the mixing of screw and barrel, and the continuous heating to maintain the suitable temperature, the material will become molten type. Squeezing and pressurizing the material, it will be transported to Extrusion Filter where the impurities are removed out. Then flow into the Extrusion Die Head for film blowing.

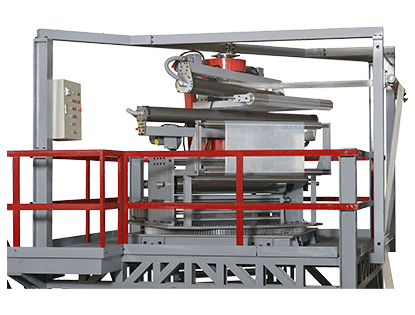

Blown Flim Take-Up Unit (Haul-Off)

The Take-Up Unit (Haul-Off) is a device set at the highest part of the Plastic Film Blowing Machine and main to pull up the blown film bubble tube which extruded out from the Die Head. The main function of Take-Up Unit is to flatten the bubble tube into lay flat film for the following process of Blown Film Winder. Further, the line speed (take-up speed) is the primary device to control the film thickness and the stability of film as well.

Blown Film Winder

Extrusion Blown Film Winder is the last process of Plastic Film Blowing Machine to produce plastic film products. To maintain the tension of film and make it easy to use for post-processing, the role of Extrusion Winder in Plastic Blown Film Line is extremely significant. Ensure the film which came from the Take-Up Unit is flat type and the final step should keep the film stably without any uneven. Film Winder. Further, the line speed (take-up speed) is the primary device to control the film thickness and the stability of film as well.