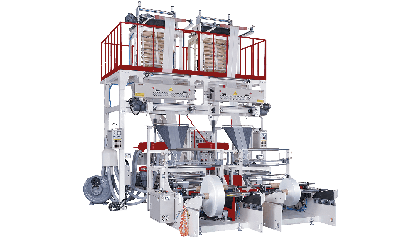

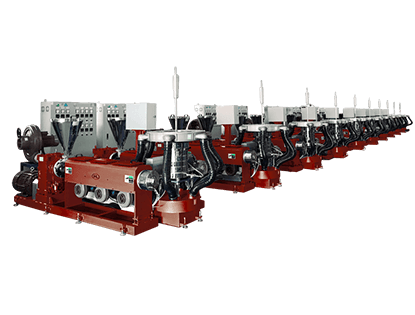

ABA/DOUBLE Film Blowing Machine

The main characteristics of these Co-Extrusion Machines, including ABA/Double Film Blowing Machines, involve the ability to use two or more materials to manufacture film. Eterlong offers customized machine specifications for different outputs, materials, film widths, and film thicknesses specific to Co-Extrusion and ABA/Double Film Blowing processes. Furthermore, these machines reduce material costs by minimizing waste and enable the addition of CaCo3, recycled materials, and color masterbatch in the middle layer to suit various application needs.

- Fast material change

- Material cost reduction

- Customized services for blown film machines with different film width

| Model | HL45 Extruder | HL55 Extruder | HL65 Extruder |

|---|---|---|---|

| Material To Be Used | HDPE / LDPE / LLDPE | HDPE / LDPE / LLDPE | HDPE / LDPE / LLDPE |

| Layflat Film Width | MAX : 550 mm | MAX : 900 mm | MAX : 1100 mm |

| Extrusion Output | MAX : 38 ~ 45 kg/hr | MAX : 60 ~ 80 kg/hr | MAX : 120 ~ 140 kg/hr |

| Film Thickness |

HDPE : 0.015 mm ~ 0.15 mm LDPE: 0.02 mm ~ 0.2 mm |

HDPE : 0.015 mm ~ 0.15 mm LDPE: 0.02 mm ~ 0.2 mm |

HDPE : 0.015 mm ~ 0.15 mm LDPE: 0.02 mm ~ 0.2 mm |

| Screw Dia | 45mm, L/D = 30:1 | 55mm, L/D = 30:1 | 65mm, L/D = 30:1 |

| Gear Box | 20 HP | 30 HP | 50 HP |

| Driving Motor | 20 HP | 30 HP | 50 HP |

| Air Cooling Fan | 2 pcs | 3 pcs | 4 pcs |

| Die Head | HDPE : 50 ~ 80 mm | HDPE : 90 ~ 120 mm | HDPE : 150 ~ 180 mm |

| Filter | 45 mm | 55 mm | 65 mm |

| Air Blower | 3 HP | 5 HP | 7.5 HP |

| Type | Individual Box | Individual Box | Individual Box |

| Heating Zone | 5 Point Temperature Control | 6 Point Temperature Control | 7 Point Temperature Control |