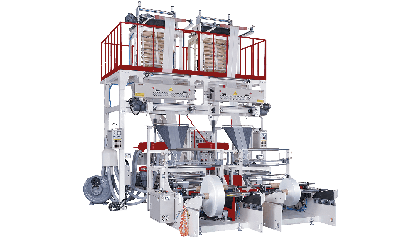

blown film

extrusion machine parts

Eterlong offers a comprehensive range of blown film extrusion machine parts designed to enhance the efficiency and quality of your production line. From extrusion die heads, which serve as the "heart" of the machine, ensuring precise film thickness, to rotary die heads that deliver superior film flatness, our parts meet the demands of various industries including food packaging, agriculture, and medical applications. Additional components like extruder filters protect your system from contaminants, while blown film bubble cages/stabilizers ensure bubble tube stability for consistent film output. Our parts are engineered for durability, precision, and compatibility with diverse polymers and machine configurations.

Extrusion Die Head

Blown film extrusion is a key process in producing various plastic films used in food packaging, industrial applications, agriculture, and medical industries. Common materials include LDPE, HDPE, PP, and PE.

At the core of this process is the blown film die head—often referred to as the "heart" of the plastic film blowing machine. Its primary function is to distribute the molten polymer uniformly, ensuring consistent film thickness across the entire circumference of the tubular film. A well-designed die head is essential for achieving high-quality film with excellent optical and mechanical properties.

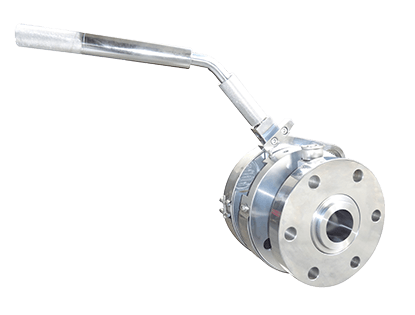

Extruder Filter

Extruder Filter is an essential component in the Plastic Film Blowing Machine which is called the cleaner. It protects the flow channel from damage by the dusty and filter the contaminants out as well. Depends on the different materials and extruders, customers are able to choose different types of filters to meet their requirements. Filter is allocated between the Extruder and the Extrusion Die Head. In order to fit the different types of feeding system and adjust the layout of equipment, it is available to install extra adapter, connector and joint for Filter. Furthermore, Filter increases friction drag of the bleeding material to bring back pressure and make the material mix well.

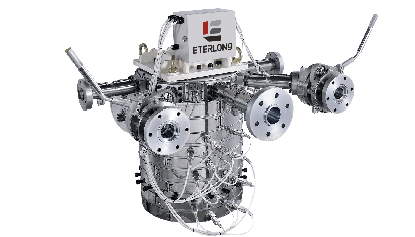

Rotary Die Head

With the change of marketing trends and shortage of manpower, the use of Extrusion Die Head has become a new choice in recent years. Considering the product quality and material cost, the Rotary Die Head brings the new business opportunity to the extrusion market. Rotary Die Head is mainly to increase the average of film thickness and ensure the flatness of film when winding. In order to maintain the average of film thickness, Rotary Die Head keeps rotating with the same speed. Besides, the Rotary Die Head distributes the uneven variations uniformly in order to upgrade the evenness of film and to reduce the ratio of thickness tolerance to the minimum. Without the rotation, the film will wrap unevenly and roll irregularly which causes the uneven thickness of film then lead to the gauge bands on the process of Blown Film Winder. Comparing fixed type die heads, the Rotary Die Head is the best option if your products require precision film thickness.

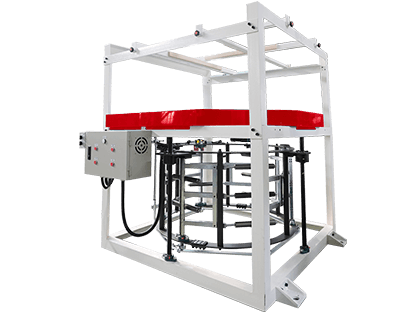

Blown Film Bubble Cage / Stabilizer

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Blown Film Bubble Cage / Stabilizer play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage / Stabilizer maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage / Stabilizer.