Troubleshooting

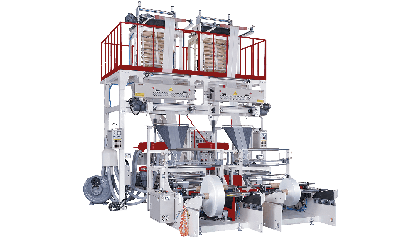

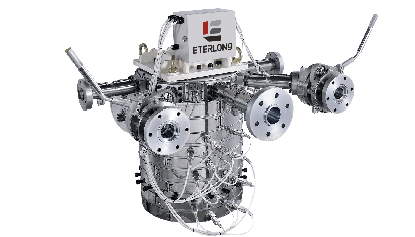

At Eterlong, we help production teams worldwide solve common blown film challenges—such as film breakage, speed fluctuations, sealing defects, and poor printability. Even small issues can impact efficiency and product quality.

Based on decades of experience and real client feedback, this guide offers quick, practical solutions to keep your production running smoothly—whether you use Eterlong machines or not.

Need personalized support?

Our technical team is ready to assist you with expert advice and tailored solutions—just reach out.

Cause (s)

Possible Solution (s)

Unstable die head temperature

- Check the heater function is normal

- Check the thermocouple position is correct

Die head throughput fluctuations

- Adjust the die gap

- Regular cleaning of die head, screw and hilter

Non-uniform cooling air volume

- Check air ring for dirt buildup or breakage

- Adjust air ring position

- Check whether air pipe is damaged

The air flow in the factory is too fast

- Do not let outdoor air directly enter the factory

Extruder throughput instability

- Cool down the hopper throat to avoid plastic blocking

- Replace the strainer meshes of Filter to avoid blocking

- Matter of the formula

Cause (s)

Possible Solution (s)

Blow-up ratio

- Use a smaller die head to increase the blow-up ratio

Improper die design or scratches

- Clear die impurities

- Fix scratches on the die head

- Avoid seams by design

Material cracking

- Change the material

- Turn down heating temperature

Inappropriate raw material formula

- Select raw materials with suitable Melt Index (MI)

- Select compatible additives

Uneven gels mix

- Use screw with a greater L/D

- Adjust the melt temperature

- Use multi-layer strainer meshes for filter, or reduce the die gap, to improve back pressure

Cause (s)

Possible Solution (s)

Improper film roll storage

- Avoid piling up

- Store in a well-ventilated place

Winding tension is too high

- Adjust the winding tension

Nip roller pressure is too high

- Reduce nip roller pressure

Tubular film temperature is too high

- Increase cooling air volume of air ring

- Use cold air cooling

- Reduce die head temperature

- Equip take-up roller with waterway

Unsuitable material formula

- Add anti-phase adhesive or slippery agent

Cause (s)

Possible Solution (s)

Tubular film asymmetry or swing

- Adjust the air flow of air ring

- Avoid too fast air flow inside the factory

- Use a hash-shape frame to steady the film

Inappropriate nip roller

- Align nip roller and keep it horizontally

- Avoid nip roller damages

Improper collapsing frame

- Adjust collapsing frame angle

- Adjust collapsing frame length

- Reduce friction to collapsing frame

Uneven winding tension

- Adjust the winding angle

Die head scratches

- Refinishing die scratches

Cause (s)

Possible Solution (s)

Improper operating in material exchange

- Avoid overheating of the gels

- The new material should have a lower MI than the old material

- Clean the machine before exchanging the material

Melt temperature is too high or too low

- Adjust the melt temperature

- Check the heater function

Raw materials contain impurities

- Avoid dirt entering feed hopper

- Avoid using recycled materials

Uneven gels mix

- Increase back pressure

- Use screw with a greater L/D

- Avoid existence of dead corner at extruder or die head

Cause (s)

Possible Solution (s)

Melt temperature is too high or too low

- Adjust the melt temperature

Improper use of additives

- Reduce color masterbatch

- Reduce waste recycling rate

Insufficient melt mix

- Add more strainer meshes of filter or reduce the die gap to increase back pressure

- Use screw with a greater L/D

Non-smooth material feeding

- Clean die head and screw & barrel

- Replace the strainer meshes of filter to avoid blockage

- Cool down the hopper

- Remove raw materials impurities

Cooling line too low

- Raise the cooling line

Cause (s)

Possible Solution (s)

Inappropriate ink

- Choose the right ink

Improper use of additives

- Reduce the amount of additives

- Use the appropriate surface lubricant

Insufficient corona treatment

- Increase the treatment voltage or wattage

- Reduce the take-up speed

- Narrow the gap of the electrode

- Raise the electrode treatment temperature

Air humidity too high

- Reduce the air humidity