Blown Film Machine

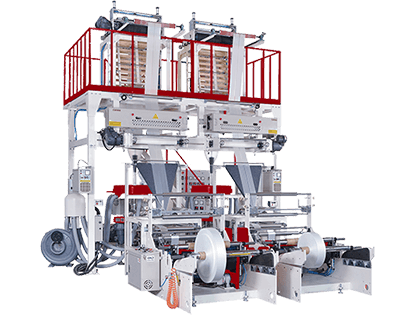

Eterlong’s blown film machines are designed for efficient and reliable production of plastic films used across industries—including food packaging, agriculture, medical supplies, textiles, and industrial applications. Each machine is built with precision extrusion technology to ensure consistent film thickness, high clarity, and mechanical strength.

Our product line includes mono-layer and customizable multi-layer blown film machines models, tailored to meet specific production demands. Whether you're producing LDPE, LLDPE, mLLDPE, HDPE, PP, or composite films, Eterlong delivers flexible solutions with stable output, user-friendly control systems, and energy-efficient operation.

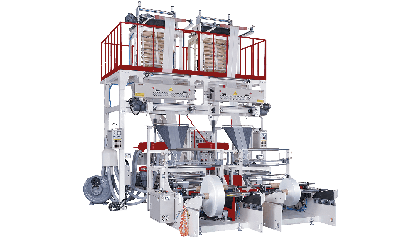

Offering a wide range of Blown Film Machine and its related components which are available to all the countries is what Eterlong keeps working on. For Three Layers ABA Co-Extrusion Blown Film Machine which characteristic is focus on its well performance and changing speed of the materials is extremely fast. It saves more time for customers to change the material and shorten the labor time. Further, It lowers the material change time and reduces the material wastage as well which is the biggest advantages of this type of plastic film blowing machine.

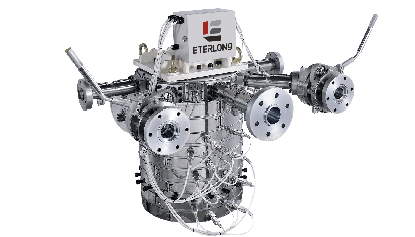

With decades of extrusion expertise, Eterlong’s Multi-Layers Co-Extrusion Blown Film Machine delivers high-quality films by precisely controlling 3 to 9 layers. Designed for modern production needs, it ensures uniform thickness, excellent barrier performance, and superior clarity.

Our customizable system adapts to various materials and applications, helping reduce waste and production costs. From design to implementation, we work closely with clients to meet their specific needs.

Eterlong offers a reliable, cost-effective solution for high-performance film production.

LDPE and HDPE Blown Film Machine is commonly used type in the blown film industry. This is the most economical type which ETERLONG has rich manufacturing experiences for many years. Most of its final applications are widely used in our daily life which from people’s livelihood to the rising industry of biodegradable. Despite there are lots of advantages in other types of Blown Film Machine, Single Layer LDPE and HDPE Blown Film Machine is still a great choice for use of many applications.

Key Features of Our Blown Film Machines

-

Stable Output and Consistent Film Quality

Equipped with precision extrusion and cooling systems to maintain even film thickness and excellent optical properties. -

Mono and Multilayer Configurations

Available from single-layer up to 9 layer co-extrusion models to meet diverse film structure requirements. -

Energy-Efficient Operation

Advanced heating zones and inverter-driven motors reduce energy consumption while maximizing productivity. -

User-Friendly Controls

Intuitive interface with temperature monitoring, speed control, and real-time diagnostics for easier operation and troubleshooting. -

Customizable Design

Die head type, film width, and output capacity can be tailored to match your production needs and material characteristics.

Applications of Blown Film Machines

Eterlong’s blown film machines are widely used in various industries, including:

- Food Packaging – High-clarity films with excellent sealing and barrier properties

- Agricultural Film – UV-resistant and durable films for greenhouse and mulch applications

- Industrial Packaging – Thick films for heavy-duty wrap and product protection

- Medical Film – Thin, hygienic films with precise thickness control

- Textile Packaging – Soft films with anti-static properties for clothing and fabric wrapping

Why Choose Eterlong Blown Film Technology?

With decades of proven expertise in extrusion system design and manufacturing, Eterlong offers blown film machines renowned for their performance, reliability, and versatility. We collaborate closely with our clients to deliver customized solutions that align with specific raw materials, film properties, and market requirements.

Whether you're producing mono-layer films or managing complex multi-layer applications, Eterlong machines are engineered for long-term durability, low maintenance, and stable, high-quality output. For businesses seeking efficiency, flexibility, and long-term value, Eterlong is the partner you can trust.